- ADDISPACE PROJECT FINAL EVENT -

- After three years of development, ADDISPACE - the project supported by the INTERREG SUDOE program, comes to an end. The final event will be the "Metal Additive Manufacturing Conference", organized together with TRANSFRON3D, in which the results achieved in both projects will be presented.

- This event will take place on June 13th 2019 in ORONA-IDEO, Hernani, Spain.

- The conference is open for everyone, upon application - Apply here

- It will feature special guests who will present their strategies for the implementation of additive manufacturing technologies in their organizations.

- Attendees will have the opportunity to hold B2B meetings in an exclusive space that will be enabled for these meetings.

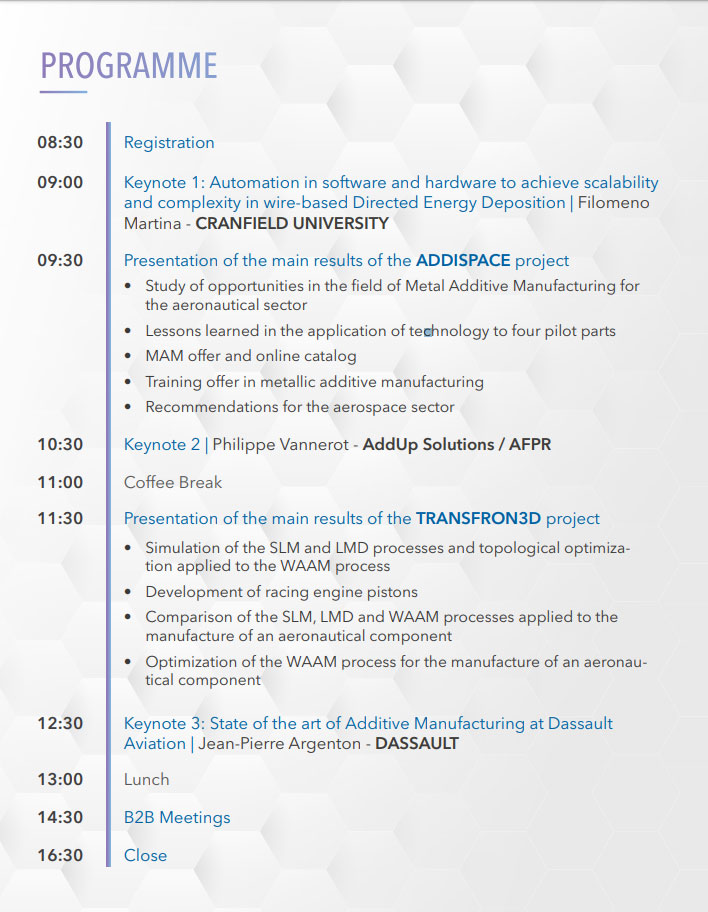

ADDISPACE Final Conference on Metal Additive Manufacturing Programme

- ADDISPACE is a project from the Interreg Sudoe Program, with the aim to provide an answer to the limited adoption of AM technologies used to manufacture metal parts in the aerospace sector.

Lack of information information about existing AM technologies, high investment costs, insufficient reliability of manufactured products, and absence of specialized, skilled and trained labour are some of the constraints ADDISPACE identified and worked for this 4 past years to overcome, through dissemination and transfer. - Now it has to present results such as a catalog of the existing offer in France, Spain and Portugal, 4 demonstrators of the aerospace sector manufactured by various metallic additive manufacturing techniques, a series of courses and trainning material and a permanent cooperation platform between the agents involved.

- GO TO ADDISPACE WEBSITE

- TRANSFRON3D has been funded by the cross-border POCTEFA program. The main challenge of the TRANSFRON3D project is to evaluate additive manufacturing processes to manufacture metallic components with a high added value compared to traditional processes.

- For the past 3 years TRANSFRON3D has been characterizing materials and processes, studied the simulation, optimization and comparison with their respective manufacturing processes. as well as testing the prototypes for validation. Specifically, the project has developed a prototype for a competition motorcycle sector and three for the aeronautical sector that have been redesigned and topologically optimized.

- 28/05/2019