AUTOMATION & ROBOTICS

AUTOMATION & ROBOTICS

Stand Alone Equipment

STAND ALONE EQUIPMENT

Production or Assembly Line

PRODUCTION OR ASSEMBLY LINE

Robotics & Vision Systems

ROBOTICS & VISION SYSTEMS

Development, production and implementation of Industrial Automation solutions

Development, production and implementation of Industrial Automation solutions

Development and manufacturing of machinery and industrial equipment is Micronorma's Core Business, being the area in which our Design & Development team is more dedicated to.

- Development and manufacturing of machinery and industrial equipment is the area we consider our Core Business, as well as industrial automation and custom tailored solutions, being the area in which our Design & Development team is more dedicated to.

- Micronorma develops all types of industrial equipment, stand alone, inline, manual or semi-automatic, all with safety regulation, CE certification. Industrial automation and vision systems integration.

- We supply our clients with turn-key solutions that include design, development, manufacturing and assembly, onsite training and startup of equipments, and after sales services.

- We also have the capability of providing services in automation & robotics, not only as an integrated part of our solutions and equipment's but as a service on its own: industrial automation, robotics, robotics maintenance and vision systems.

- We hold vast knowledge and experience working for the automotive, energetic and electronic sector.

- Some of our solutions:

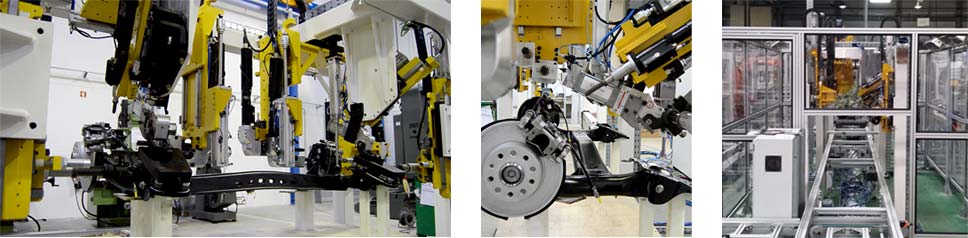

FULLY INTEGRATED ASSEMBLY LINES

FULLY INTEGRATED ASSEMBLY LINES

Assembly line

- We also have the capability to develop systems to fully integrate our customers’ assembly lines.

Assembly line

-

Automatic line for feeding, conveying, heating and picking & place of components

Rear axle screwing system integrated into assembly line

-

Rear axle screwing system integrated into assembly line

Capacitor impregnation line

-

Capacitor Impregnation Line

- Automatic line for feeding, tray management, impregnation system and vacuum cleaning of capacitors

Vials Palletizing Line

-

Vials Palletizing Line

- Automatic vials palletizing line for the pharmaceutical industry with a rate of 400 vials per minute.

- Consisting of an accumulator conveyor, a vacuum pick & place station and a robot palletizing station.

Single Unit Work Cells

SINGLE UNIT WORK CELLS

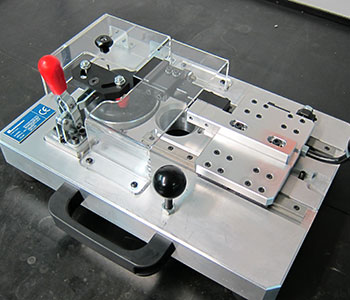

Pedal Assembly Equipment

-

Pedal Assembly Equipment

- Semi-automatic station for pedals assembly.

- Customizable for operations such as sub-assemblies, poka-yoke, riveting and/or screwing, final validation and marking.

Marking Equipment

-

Marking Equipment

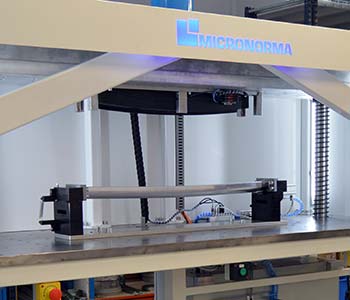

Profile Bending Press

-

Profile Bending Press

- Fully automated hydraulic press to bend profiles

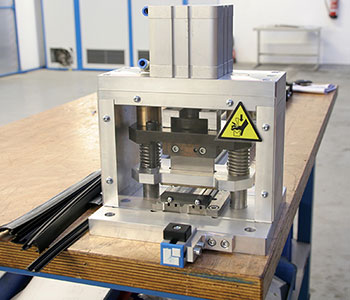

Rail Drilling Equipment

-

Rail Drilling Equipment

- Fully automated equipment to positioning and drilling of 1 pair of rails with 11 drill holes with different diameters (5 x ø9mm e 6 x ø5,2mm) in each rail in 3 sequential operations.

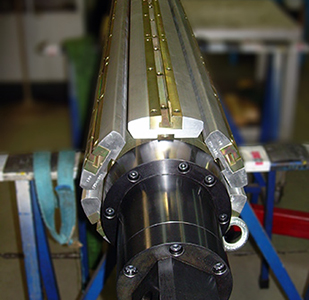

Roof Rail Assembly Equipment

-

Roof Rail Assembly Equipment

- Equipment to mount clip and endcap parts on roof rails

ROBOTICS

ROBOTICS

Robotics

- Our solutions can integrate robots or cobots for the most diverse functions, such as pick & place, welding, screwing, among others.

VISION & SENSOR SYSTEMS

VISION & SENSOR SYSTEMS

Vision & Sensors

- Micronorma integrates vision cameras and other types of sensors in its solutions, both to ensure the effectiveness, safety and automation of the process, or as an integral part of the process, for validation and inspection operations.

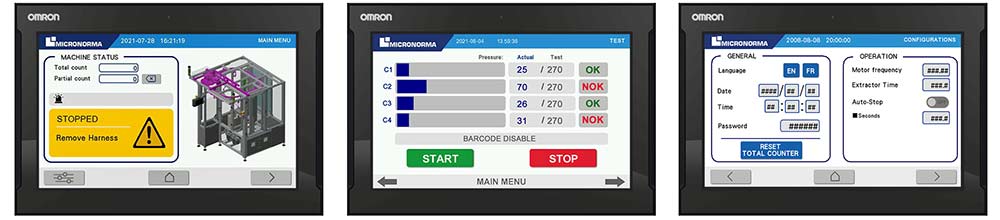

AUTOMATION & HMI

AUTOMATION & HMI

HMI

- Micronorma develops the control interface for the tailored-made equipment it produces, considering user-friendlyness and easiness.

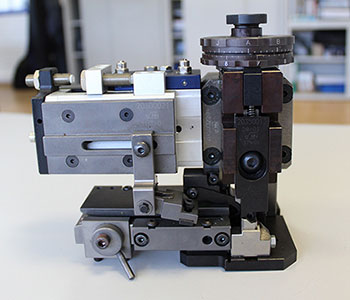

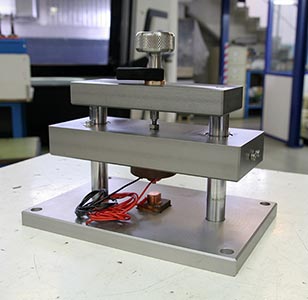

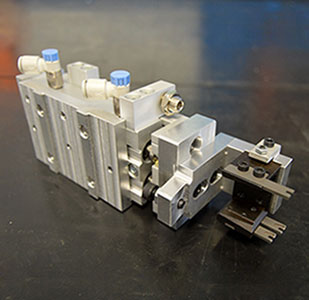

TOOLS, DEVICES & MACHINE MODULES

TOOLS, DEVICES & MACHINE MODULES

Tools & Devices

- We develop and produce a wide range of tools and devices for several purposes like pressing, cutting, bending, drilling or other operations.

UPGRADES & RETROFITS

UPGRADES & RETROFITS

Upgrades & Retrofits

- Micronorma performs upgrades and retrofits to any existent equipment, even if the equipment was developed by another manufacturer.