VISION SYSTEMS

VISION SYSTEMS

VISION & SENSOR SYSTEMS

VISION & SENSOR SYSTEMS

Vision Systems

A vision system is a type of technology that enables computers to interpret visual data, essentially enables them to see.

- A vision system is a type of technology that enables computers to interpret visual data, essentially enables them to see.

- It is a complex system that uses various algorithms and techniques to analyze images and videos in order to extract useful information, such as object recognition, tracking, and measurement.

- A vision system typically consists of several components:

- -Camera or capturing imaging device to gather the visual data

- -Hardware computer or processor or analyze the data

- -Software and specialized algorithms to performs the necessary calculations and tasks such as image segmentation, feature extraction, and pattern recognition.

What are vision systems used for?

-

What are vision systems used for?

- Machine vision systems are used in a wide range of applications, including manufacturing, robotics, security, and others. They can be used to automate processes, improve quality control, and provide insights and analysis that would be difficult or impossible for humans to perform manually.

- Machine vision systems can also perform several tasks such as recognition and identification, inspection, guidance, counting and measuring. Vision system are also a crucial part of robotics allowing the robot to analyze, make decisions and interact with the environment.

Vision systems improve quality and productivity of manufacturing, while reducing costs

-

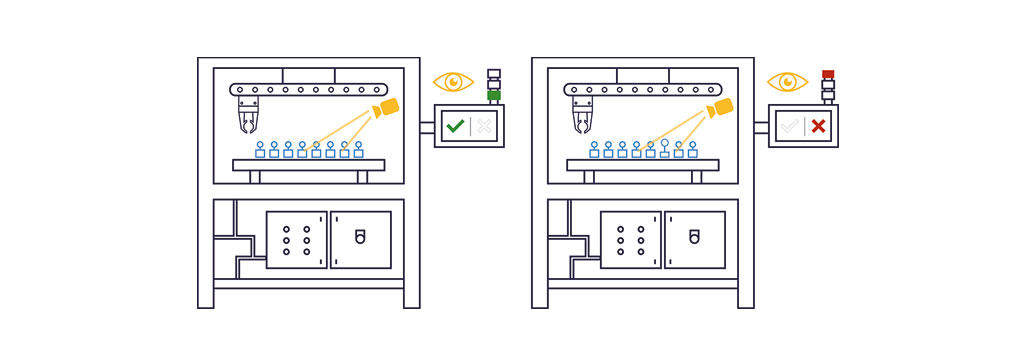

Vision sensors improve quality and productivity of manufacturing, while reducing costs

- A vision system is a complex system needed for complex applications like helping a robot interact with parts in an automated factory.

- There are a lot of other solutions based on integration of vision cameras and sensors to help improve a manufacturing process. These solutions provide the system a simple yes/no answer to help the system determine the next step of the cycle, and are great for several purposes such as detect presence or absence, identify, inspect or count with great speed, accuracy and repeatability.

Micronorma integrates vision sensors & systems

-

Micronorma integrates vision sensors & systems

- Micronorma integrates vision cameras and other types of sensors in its solutions, both to ensure the effectiveness, safety and automation of the process, or as an integral part of the process, for validation and inspection operations.

-

APPLICATION EXAMPLES:

- CONNECTOR ASSEMBLY AND INSPECTION EQUIPMENT

- In this equipment for assembling connectors, the vision system is used to inspect the assembly.

- This system uses two cognex cameras mounted on a sliding guide to simultaneously capture images of the upper and lower plane of the two left and right connectors, respectively.

- Connectors are assembled manually and it is necessary to check the quality of assembly. The system checks for the presence or absence of the sleeve in the holes, slots and limits of the connector.

- Only after the assembly has been validated is the connector crimped at the next station, thus avoiding adding value to a non-conforming product, minimizing rework costs and non-conformities.

Connector Assembly and Inspection Equipment

-

PRODUCTION LINE PARTS INSPECTION SYSTEM

- In this production line, a vision system for parts inspection was installed. Four cognex cameras are used to simultaneously inspect 2 parts, capturing images from two different planes of each part. Non-conforming parts are segregated, only those parts that meet the quality requirements advancing to the next phase of production.

Production Line Parts Inspection System

-

MASS APPLICATION AND INSPECTION EQUIPMENT

- In this example, a vision system was applied to a device for dosing protective grease on connectors.

Visual inspection verifies that the connector cavities have been properly sealed with the protective grease. - In this solution a Cognex IS2000 vision sensor was applied.

Mass Application and Inspection Equipment

-

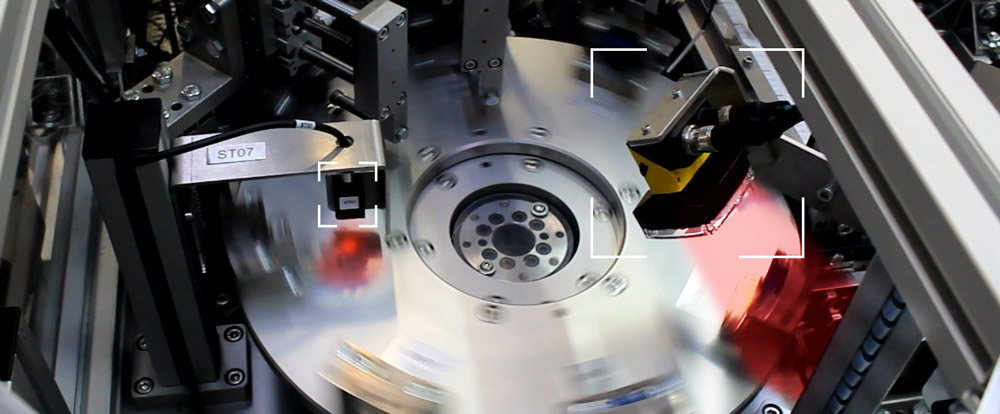

AUTOMATIC CONNECTOR ASSEMBLY STATION

- This vision system example was applied to an automatic connector assembly station.

- This station prepared for 5 different connector configurations (composed of 2 parts: Housing and Front Holder) includes two feeders, a turntable with 8 stations, and HMI.

- The visual inspection initially consists of validating the Housing and then validating the assembly and the final product, identifying and indicating various types of defect: missing parts; damaged connector; incorrect color; defective assembly; nonconforming final product.

- The Cognex In-Sight 2000 vision sensor with a 16mm lens and photoelectric sensors from Omron E3T and E3Z were used in this solution.

Automatic Connector Assembly Station